Turn-mill combination parts are Compound processing that is one of the most popular processing techniques in the field of mechanical processing in the world. It is also an advanced manufacturing technology.

Turn-mill combined parts with compound processing are the realization of several different processing techniques on one machine tool. The most widely used and most difficult compound machining is turning and milling compound machining. The turn-mill composite machining center is equivalent to a combination of a CNC lathe and a machining center.

Turn-mill combination parts for compound machine tools are the fastest growing and most widely used CNC equipment among compound processing machine tools. The purpose of compounding is to make a machine tool have more Functionality, can complete multiple tasks in one clamping, improve processing efficiency and processing accuracy.

In order to improve the processing efficiency and precision of complex special-shaped products, technicians have been looking for effective and accurate processing methods. The emergence of turning and milling compound machining equipment provides an effective solution for improving the machining accuracy and efficiency of parts. Our custom turn-mill composite parts have stable machining quality and high machining accuracy, and are suitable for complex machining requirements.

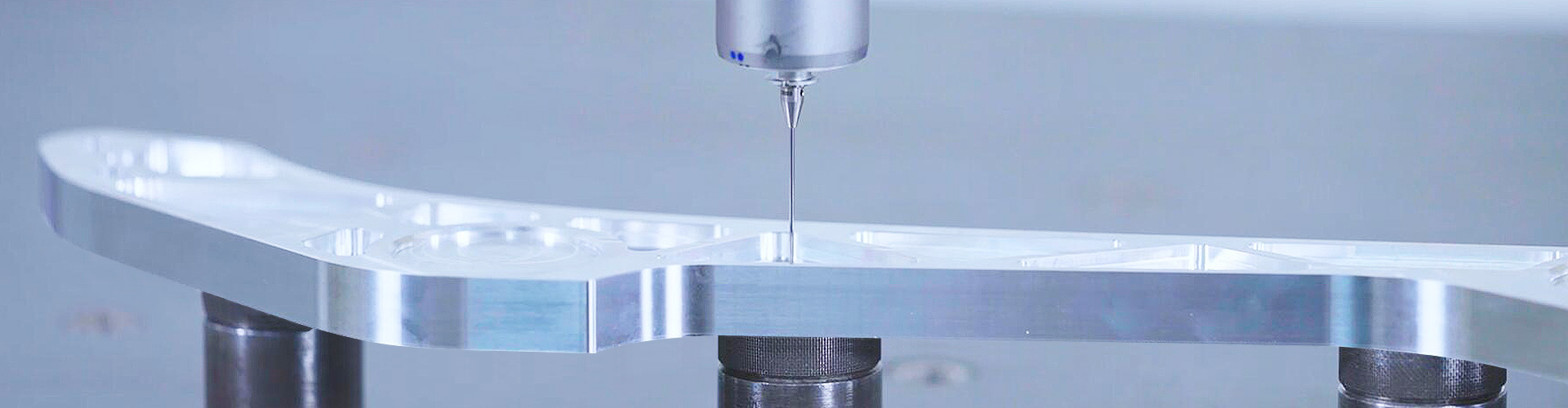

Turn-Mill combination High quality Medical Parts Such products are precision parts of medical equipment and are precision machined from aluminum alloy, stainless steel, carbon steel etc. The difficulty of the finished product is that there are many fine holes and the precision hole tolerance is controlled within +/-0.005mm. It is processed by CNC lathes or core machines. The outer contour of the product is turned, and then the grooves and fine holes are precisely machined by the CNC machining center.

We focus on the production of high-precision technical parts with a strong technical background, advanced equipment and professional R&D engineers for supporting. we supply Turn-mill Combination Metal Parts with high precision machining and high quality parts. The CNC machining center for turning-milling composite processing is a high-efficiency, high-precision CNC machine tool. The workpiece can be processed in multiple processes in one clamping. At the same time, it also has a tool library and an automatic tool change function. The CNC machining center can realize the linkage control of three axes or more to ensure that the tool can process complex surfaces.

we supply Turning-milling Combined Robotic Parts with high precision machining and high quality parts. The most widely used and most difficult compound machining is turning and milling compound machining. Turning-milling compound machine tools are also the fastest growing CNC equipment among compound processing machine tools. Shorten the product manufacturing process chain and improve production efficiency. We focus on the production of high-precision technical parts, especially like Robots parts with a strong technical background, advanced equipment and professional R&D engineers to support.

we supply complex muli-axis linka CNC parts in aero-engine including impeller,Closed blisk and Multi-stage molecular pump blades. We are a precision manufacturing company integrating development, design, production and sales. Our main products are precision components for Aerospace, Telecommunication, Gas control,Medical and Auto industry etc. We have been passed ISO 9001 and AS 9100D certified for over 20 years, NADCAP - NDT (magnetic particle inspection) certified in 2019. and also has implemented an ERP system since 2018 and lean manufacturing system since 2020.