CNC machining parts for household appliances are precision-engineered components that form an integral part of various appliances used in homes. These components are made using advanced CNC machining techniques, which provide superior accuracy, speed, and consistency. The CNC machining process involves cutting, drilling, and shaping a workpiece to exact specifications using computer-controlled tools and cutting machines. You can rest assured to buy customized CNC Machining Parts For Household Appliance from us. Sunbright look forward to cooperating with you, if you want to know more, you can consult us now, we will reply to you in time!

CNC Machining Parts For Household Appliance

CNC Machining Parts For Household Appliance Introduction

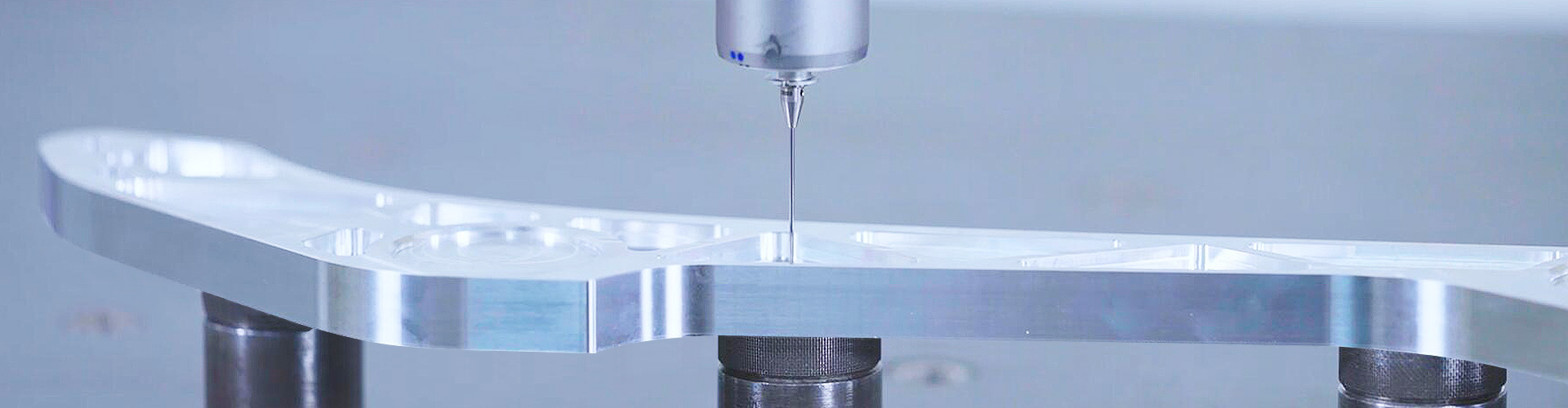

CNC machining parts for household appliances are precision-engineered components that form an integral part of various appliances used in homes. These components are made using advanced CNC machining techniques, which provide superior accuracy, speed, and consistency. The CNC machining process involves cutting, drilling, and shaping a workpiece to exact specifications using computer-controlled tools and cutting machines.

At our facilities, we specialize in the design and manufacturing of CNC machining parts for household appliances. Our highly skilled technicians and engineers utilize state-of-the-art equipment and software to produce high-quality CNC machining parts that meet or exceed the expectations of our clients in the household appliance industry.

The CNC machining parts for household appliances come in different sizes, shapes, and materials, including aluminum, brass, copper, stainless steel, and plastic, among others. Depending on the specific application, these components can be designed as simple or complex as needed to achieve the desired functionality and performance.

Our CNC machining parts for household appliances are used in various appliances, including refrigerators, washing machines, dryers, kitchen appliances, and other home appliances. Some examples of CNC machining parts that we produce include bearings, gears, pulleys, shafts, and housings.

At our facilities, we pay attention to detail in the design and production of CNC machining parts for household appliances. We use advanced quality control techniques to ensure that each component is compliant with the desired measurements and specifications. Our parts undergo rigorous testing to ensure that they meet or exceed industry standards such as durability, reliability, and functionality.

In summary, CNC machining parts for household appliances are precision-engineered components used in various appliances found in homes. These parts are made using advanced CNC machining processes and come in different sizes, shapes, and materials. Our facilities specialize in the manufacture of high-quality CNC machining parts that meet or exceed industry standards and can be found in various home appliances.

You are welcomed to come to our factory to buy the latest selling, low price, and high-quality CNC Machining Parts For Household Appliance.Sunbright look forward to cooperating with you.

CNC Machining Parts For Household Appliance Parameter (Specification)

The surface roughness is Ra 0.1-3.2.

CNC turning work range is φ0.5mm-φ150mm*300mm

CNC milling work range is 510mm*1020mm*500mm

CNC Machining Parts For Household Appliance Feature And Application

Metal is the primary raw material used in CNC machining spare parts for home appliances.

With our technology, knowledge, and skills, we will be among the most capable and reasonably priced production sources.

Our ability to accomplish complicated projects with short turnaround times and great product quality is facilitated by our stringent adherence to ISO9001 quality system requirements, AS 9001D accreditation, and flexible bespoke engineering.

CNC Machining Parts For Household Appliance Details

All dimensions have a tolerance range of +/-0.005mm~+/-0.01mm.

These CNC turning parts for medical equipment are meticulously inspected in compliance with AS 9001D and ISO9001 standards.

We have a thorough quality control system and fully functional measuring equipment to ensure good quality.

In order to continue meeting the manufacturing demands of our customers, we have also been enhancing the CNC machining process to increase its effectiveness and quality.