Milling Parts Of Aircraft are precision-engineered parts used in the manufacturing of aircraft. These parts are made using advanced milling machines that use rotary cutting tools to remove material from a workpiece in a specific pattern. The milling process allows for the creation of complex shapes, intricate designs, and tight tolerances, making it an ideal manufacturing technique for the aerospace industry. You can rest assured to buy customized Milling Parts Of Aircraft from us. Sunbright look forward to cooperating with you, if you want to know more, you can consult us now, we will reply to you in time!

Milling Parts Of Aircraft

Product Introduction of Precision Milling Parts Of Aircraft

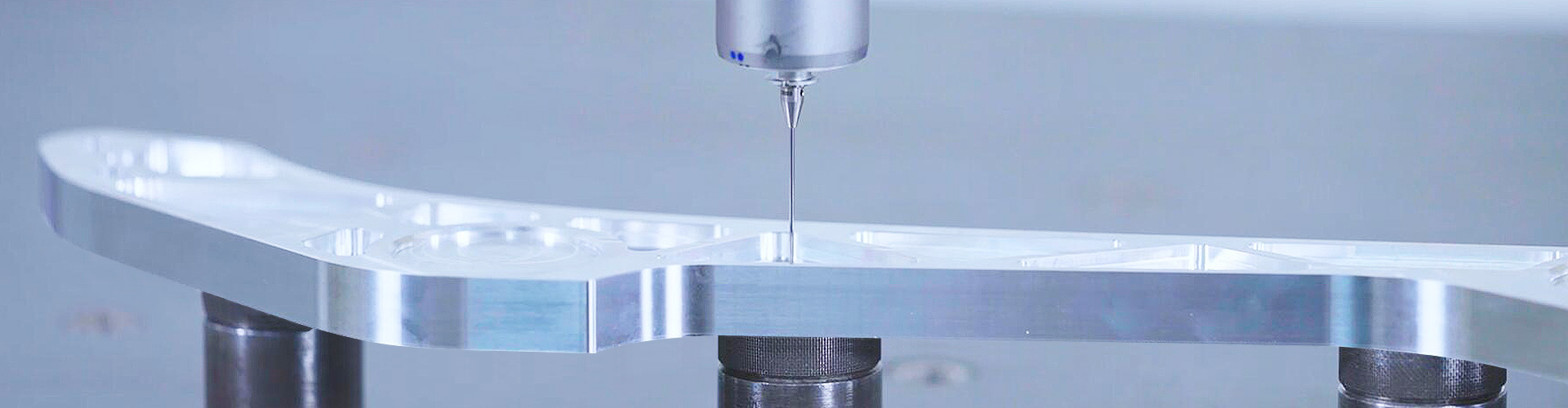

Milling parts of aircraft are precision-engineered parts used in the manufacturing of aircraft. These parts are made using advanced milling machines that use rotary cutting tools to remove material from a workpiece in a specific pattern. The milling process allows for the creation of complex shapes, intricate designs, and tight tolerances, making it an ideal manufacturing technique for the aerospace industry.

At our facilities, we manufacture high-quality milling parts of aircraft that meet the stringent requirements of the aerospace industry. Our milling parts are made from high-strength materials such as aluminum, titanium, and stainless steel, ensuring that they are lightweight, durable, and able to withstand the extreme conditions associated with flying.

Our team of skilled engineers and technicians uses the latest software tools and precision machining equipment to design and produce milling parts of aircraft to exacting standards. We specialize in the production of complex parts with intricate geometries, including wing brackets, landing gear components, engine mounts, and control surfaces.

Our milling parts of aircraft undergo rigorous quality control processes to ensure that they meet or exceed the highest industry standards. We use advanced measuring equipment to inspect every part to ensure that it meets the precise specifications required for use in the aerospace industry.

In summary, milling parts of aircraft are integral components of the aerospace industry. The milling process is ideal for producing complex parts with tight tolerances and intricate designs, making it an essential manufacturing technique for the aerospace industry. At our facilities, we specialize in the production of high-quality milling parts of aircraft using the latest software tools and precision machining equipment. Our parts undergo rigorous quality control processes to ensure that they meet or exceed the highest industry standards.

You are welcomed to come to our factory to buy the latest selling, low price, and high-quality Precision Milling Parts Of Aircraft.Sunbright look forward to cooperating with you.

Milling Parts Of Aircraft Parameter (Specification)

The surface roughness is Ra 0.1-3.2.

CNC turning work range is φ0.5mm-φ150mm*300mm

CNC milling work range is 510mm*1020mm*500mm

Milling Parts Of Aircraft Feature And Application

Aluminum is the primary raw material used in Precision CNC Aluminum Milling Machine Aircraft Machining Parts.

Aluminum has two advantages when it comes to machining operations: it is lightweight and strong.

Excellent workability, superior corrosion resistance, simpler electrical conductivity, reduced production costs, and recyclability are some of aluminum's best qualities.

Several industries, including aerospace, the medical field, the automotive industry, and others, frequently use our machining components, which have received positive feedback from clients for their excellent quality.

Milling Parts Of Aircraft Details

All dimensions have a tolerance range of +/-0.005mm~+/-0.01mm.

Strict controls are in place to ensure that these precision CNC aluminum milling machine aircraft machining parts meet NADCAP's NDT certification level, AS9100D.

We have a thorough quality control system and fully functional measuring equipment to ensure good quality.