We supply Stamping Mechanical metal Components with a full range of machining processes. We are a precision manufacturing company integrating R&D, design, production and sales. We have about more than 1,000 sets of various advanced production machines and 20 sets of high-precision testing and inspection equipment. We have passed ISO 9001 and AS 9100D certification for over 20 years. In order to meet high quality, we have detailed quality control system and full-equipped measuring equipment. Our main market is in European and the United States.

Stamping Mechanical Metal Components

1.Product Introduction

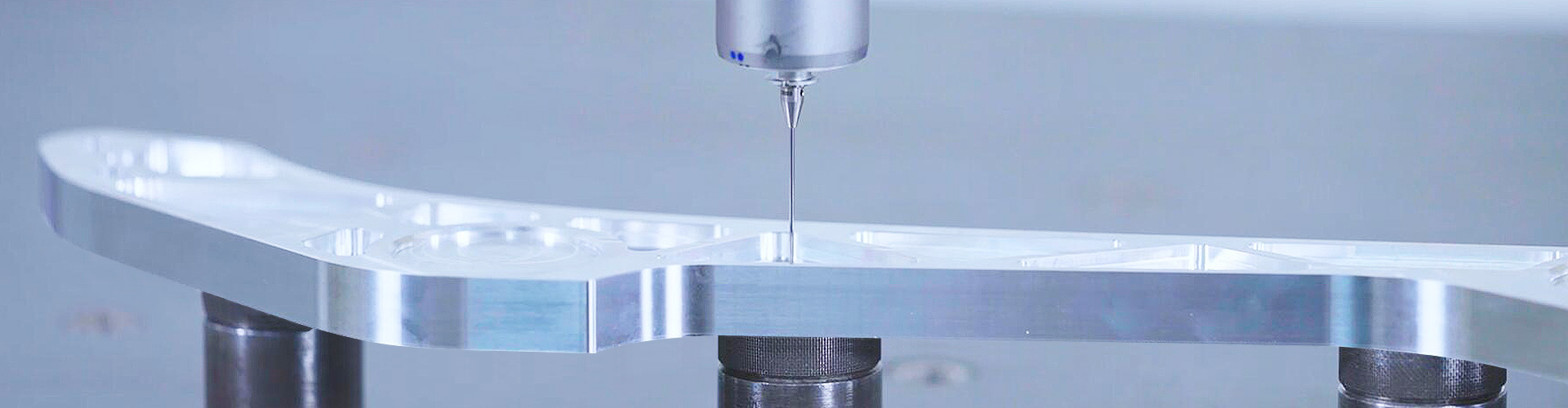

These Stamping Mechanical metal Components are used metal stamping machines.

Metal stamping machines can cast, punch, deform, and bend metals using CNC machines for precision and accurate parts.

The process of stamping can quickly create exact metal shapes with meticulous accuracy and measurements.

2.Product Parameter (Specification)

The surface roughness is Ra 0.1-3.2.

CNC turning work range is φ0.5mm-φ150mm*300mm

CNC milling work range is 510mm*1020mm*500mm

3.Product Feature And Application

There are several benefits to metal stamp. Stamping Mechanical metal Components are a cold shaping process that does not require heating to shape the metal, which makes it less expensive.

The precision and accuracy of metal stamping has made it the number one method for parts manufacturing.

These parts are used for a wide variety of industries including Medical, Electronics, Military, Aerospace, Automotive, Home appliances etc.

4.Product Details

Complex and intricate designs that are impossible to produce using any other process can easily be fabricated.

The Tolerance of all dimension is between +/-0.005mm~+/-0.01mm.

These Stamping Mechanical metal Components are controlled strictly in accordance with ISO 9001 and AS9001D NADCAP - NDT certification standard.

To meet high quality, we have detailed quality control system and full-equipped measuring equipment.

5.Deliver,Shipping And Serving

The package is standard exported package. All kinds of shipping ways can be used by express, by air and by sea.

To get approval and satisfactory from our customers ,It is necessary for us to prompt delivery, careful shipping arrangement and continuous services.

We deeply implement the customer-oriented, quality-first business philosophy.

We also implement the "Performance evaluation program" to continuously improve our technical capability, quality and management skill and service.

6.FAQ

who are we?

Sunbright is a high-tech enterprise which integrates R&D, production and sales of high-end products and precision components. Products are widely used in communications, precision instruments, medical equipment, high-speed trains, auto, aviation and other industries.

how can we guarantee quality?

The workshop and production mass are strictly control in accordance with ISO 9001 and AS 9100D certification standard. The pre-production sample confirmed before mass production, final Inspection before shipment.

what can you buy from us?

CNC precision Machining parts including CNC turning and CNC milling, Custom CNC parts, CNC auto spare parts, Die casting parts, forging parts, Injection mold,mould etc.

why should you buy from us not from other suppliers?

We are experienced in customization for over 20 years. With the concept of "pragmatism", we provide customers with one-stop high-quality solutions from raw materials to process engineering and manufacturing. Products are widely used in communications, precision instruments, medical equipment, high-speed trains, auto, aviation and other industries.

what services can we provide?

We can provide CNC precision machining service, Sheet metal fabrication service, injection plastic mold service, some full products service of Beauty Care Tools and Top ornaments.