You can rest assured to buy customized Zinc alloy die casting from us. Zinc alloy die-casting parts are zinc alloy materials that inject molten metal liquid into the cavity through pressure in the die-casting machine, and obtain the required parts after cooling, solidification, and cleaning.

You are welcomed to come to our factory to buy the latest selling, low price, and high-quality Powder metallurgy parts in brake booster vacuum pump. Vehicles equipped with gasoline engines, because the engine adopts ignition type, can generate high vacuum pressure in the intake manifold, which can provide sufficient vacuum source for the vacuum booster braking system. Most of the current vacuum pumps are connected to the intake manifold place. Gasoline direct injection engines designed to meet high emission environmental protection requirements cannot provide the same level of vacuum pressure at the intake manifold to meet the requirements of the vacuum brake booster system, so a vacuum pump needs to be installed.

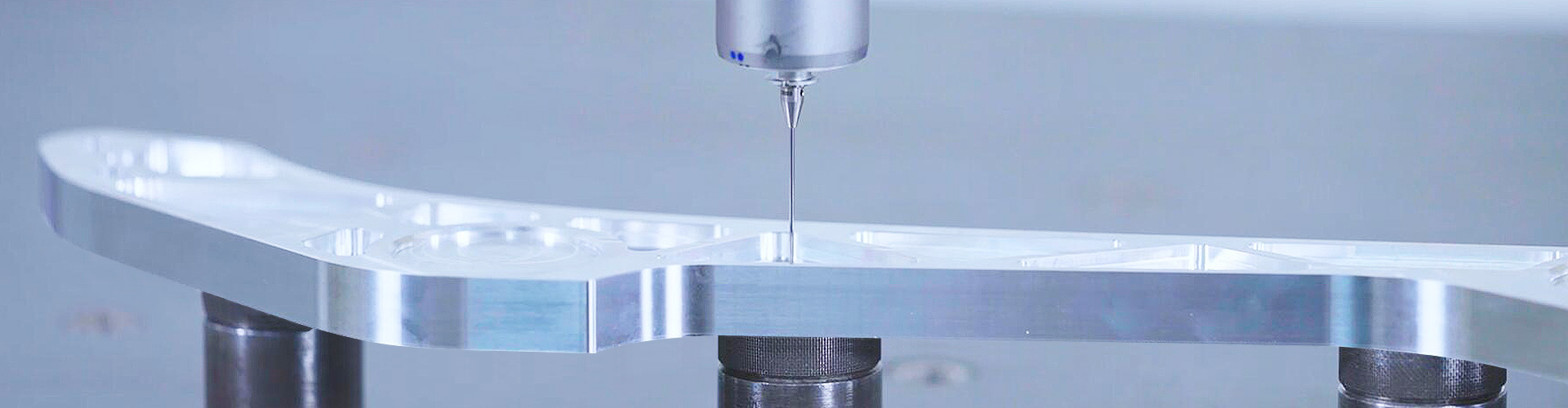

You can rest assured to buy CNC processing plastic prototype from our factory. CNC plastic processing is the main method of prototype production, mainly to process plastic materials such as ABS, PC, PA, PMMA, POM into the physical samples we need. CNC-processed samples have the advantages of large size, high strength, good toughness, and low cost, and have become the mainstream of prototype production.

As the professional manufacture, we would like to provide you Automobile door handle parts. And we will offer you the best after-sale service and timely delivery. The door handle is a switch part installed on the car door to open the car door. It is also a force-bearing part for the operator to pull the door. When the operator pulls the hand-held end on the door handle, the door handle rotates around the fulcrum to trigger the switch mechanism to start. Of course, in order to limit the pulling angle of the door handle, the door handle is provided with a block against or disengaged from the door, or it can be called a buffer block. The above-mentioned buffer block is more common in the automotive industry. The most is the use of rubber parts. Therefore, when the external ambient temperature is high, such as at noon in summer in the southern region, the temperature of the outer surface of the car door can reach 60° C. or even higher. This will lead to adhesion between the contact point between the buffer block of rubber parts and the surface of the car door, especially for vehicles parked outdoors for a long time, the buffer block of rubber parts is very easy to stick to the car door.

You can rest assured to buy Semiconductor Precision Parts from our factory. Semiconductor equipment has a complex structure consisting of thousands of components. The performance, quality and precision of components determine the reliability and stability of the equipment. The semiconductor industry follows the industrial law of "one generation of technology, one generation of technology, and one generation of equipment", and the upgrade and iteration of semiconductor equipment largely depends on the technological breakthrough of precision components. Various semiconductor components cooperate with each other to support the operation of semiconductor equipment. Compared with the basic components of equipment in other industries, the cutting-edge technical characteristics are more obvious, such as high precision, small batch, variety, special size, complex process, and strength. , strain, corrosion resistance, electronic characteristics, electromagnetic characteristics, material purity and other composite functional requirements.

As the professional manufacture, we would like to provide you Automotive precision forging parts. Due to the high strength and good toughness of the parts manufactured by the forging process, they are suitable for mass production, so nearly 60% of the parts in the car are produced by forging. More and more vehicle manufacturers are pursuing lightweight and fuel-saving rate, replacing cutting process with precision forging technology has become the main direction of new product development, all of which provide opportunities for the development of precision forging.