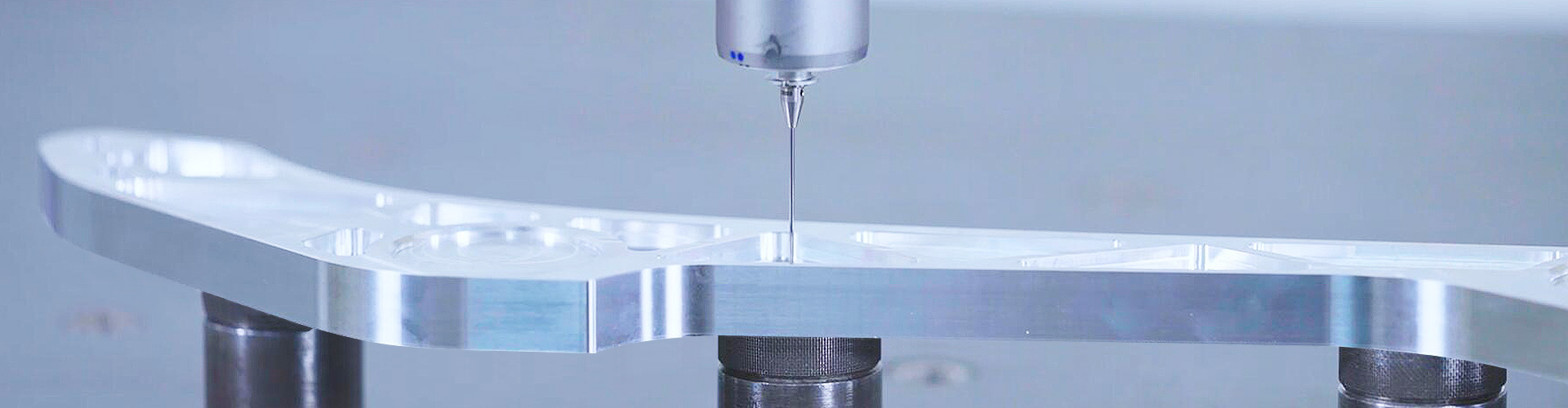

As the professional manufacture, we would like to provide you High quality aluminum alloy housing. We focus on the processing of precision aluminum alloy casings, with experience in delivering samples with more than 15600+ pen appearance parts, and the batch delivery is 20% faster than the peers. There are imported 5-axis cnc numerical control machines, the accuracy can reach ±0.01, and the surface finish can reach 0.8 microns. Subsequent rough polishing, fine polishing, deburring and degreasing - anodizing and other processes ensure the stability and consistency of product dimensions, surface finish, scratch resistance, and scratch resistance levels that meet or even exceed customer requirements. No worries about scratches and scratches when machining and assembling.

Multipurpose shaft parts are one of the more commonly used typical parts. It is mainly used to support transmission parts, transmit torque and bear loads. Shaft parts are rotating body parts, whose length is greater than the diameter, and are generally composed of the outer cylindrical surface, conical surface, inner hole, thread and corresponding end surface of the concentric shaft. According to different structural shapes, shaft parts can be divided into optical shaft, stepped shaft, hollow shaft and crankshaft. Shafts with an aspect ratio less than 5 are called short shafts, those greater than 20 are called slender shafts, and most shafts are in between.

You are welcomed to come to our factory to buy the latest selling, low price, and high-quality High precision small propeller. The high-precision small propeller contains several identical blades, one of which is obtained by rotating the other blade 180 degrees around the axis of rotation, and each blade is composed of two curved surfaces: the upper surface and the lower surface; At the tip of the propeller, the upper surface curved surface is always convex from the leading edge to the trailing edge; from the root to 50% of the radius, the lower surface curved surface shows a downward convex shape.

You can rest assured to buy customized High Precision Flange Parts from us. Flange production can be selected from four common types of forging, casting, rolling and cutting. Each process can produce high-precision flanges. As long as you have customized needs for high-precision flanges, sunbright will provide you with a design from One-stop service from production to shipment.

Investment castings have the advantages of high dimensional accuracy and the ability to cast complex thin-walled parts, and play an increasingly important role in the aerospace field. With the increasing complexity and integration of the structure and size of castings in the aerospace field, higher requirements are put forward compared to investment precision manufacturing. According to actual needs, it is particularly important to develop corresponding precision casting molding raw materials and key heat treatment equipment, control and ensure the overall dimensional accuracy of large precision casting structural parts, meet design requirements, and shorten the development cycle.

As the professional manufacture, we would like to provide you high quality Magnesium alloy auto parts. Magnesium alloy materials are the lightest engineering structural materials today, and magnesium alloys are used to manufacture automobiles.Vehicles, especially new energy electric vehicle parts, can achieve obvious energy saving and emission reduction effects.