Metal Parts Fabrication is a strong metal part made of Stainless steel,Aluminum, high carbon steel or galvanized steel through sheet metal, stamping, die-casting, forging, casting, powder metallurgy and other metal processing. It is widely used in ipping, medical, mining, automobile and aircraft manufacturing industries.For example,One of our most qualified products is Precision Aluminum Alloy Die Casting Radiator.

Metal Parts Fabrication can flexibly meet the various shapes of customized metal products in various industries. At the same time, Metal Parts Fabrication also has the advantages of high durability, easy maintenance, low cost, and environmental protection. Like Metal Accessories Casting Parts are the best application in industries field.

We supply Powder metallurgy parts machinery industry and produce various three-dimensional complex structural parts, functional parts and appearance parts according to the demands of different customers. Each part of the product has uniform organization, high dimensional accuracy, and high relative density with good surface finish. The product quality is stable, the production efficiency is high, and it is easy to realize large-scale and large-scale production.We have professional R&D engineers team with industry experience for 30 years,with rigorous and standardized control procedures for each Industry customers provide high-quality products.

We supply Powder metallurgy parts Medical equipment and produce various three-dimensional complex structural parts, functional parts and appearance parts according to the demands of different customers.

Products are widely used in communication industry, locks industry, clocks and jewelry industry, medical equipment industry, household appliances industry, automobile industry etc. We have professional R&D engineers team with industry experience for 30 years,with rigorous and standardized control procedures for each Industry customers provide high-quality products.

We supply powder metallurgy parts 5G communication base with a professional manufacturer of precision CNC machining parts, metal parts fabrication and plastic parts. Powder metallurgy is an industrial technology for preparing metal powder or using metal powder as raw materials, forming and sintering, to produce metal materials, composite materials and various types of products. MIM is short for Metal injection molding that is as a near-net-shape technology for manufacturing high-quality precision parts. It can produce small metal parts with complex shapes like plastic products.

We supply a wide range of Professional Sheet Metal Fabrication with all kinds of material and surface finished. We Manufacture a huge range of metal components, assemblies and finished surface products for various sectors and applications. Our products are widely used in communications, precision instruments, medical equipment, high-speed trains, auto, aviation and other industries. The products are mainly exported to European and the United States market. We have passed ISO 9001 and AS 9100 certificate for over 20 years, NADCAP- NDT by MPI audited certificate in 2019, and also has implemented an ERP system since 2018 and lean manufacturing system since 2020.

We supply a wide range of Laser Cutting Bending Steel Sheet Metal Parts with all kinds of surface finished. We Manufacture a huge range of metal components, assemblies and finished products for various sectors and applications.Our professional management team has a strong technical background and excellent management system, that can provide customers with high-quality products and services. At the same time, we are recognized and supported by many customers,. We deeply implement the customer-oriented, quality-first business philosophy. We also implement the "Performance evaluation program" to continuously improve our technical capability, quality and management skill and service.

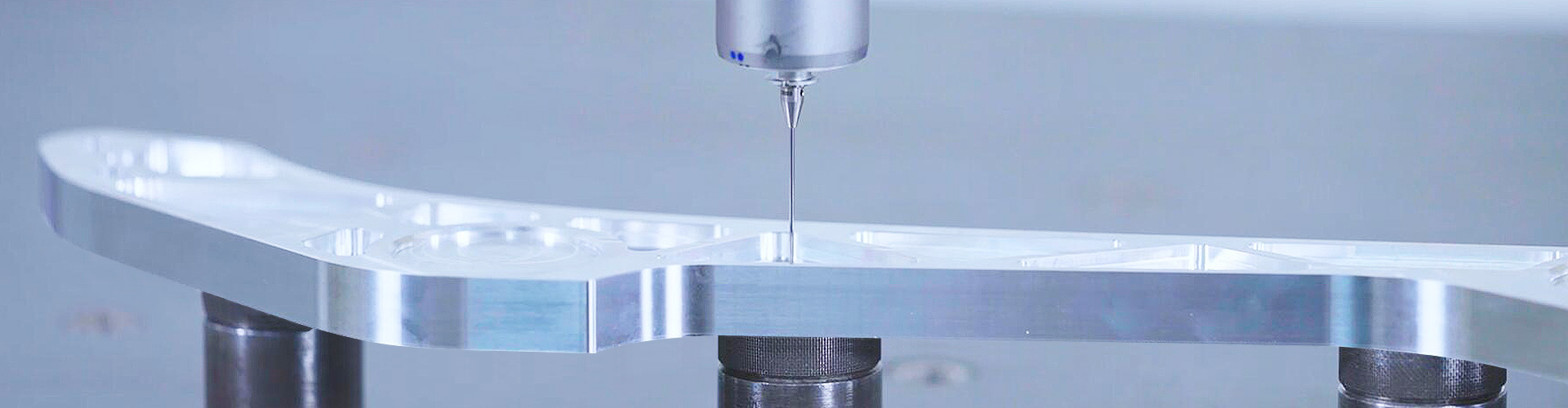

We supply a wide range of Precision CNC Machining Sheet Metal Parts with all kinds of surface finished. We are a high-tech enterprise which integrates R&D, production and sales of high-end products and precision components. Sunbright has accumulated a large number of high-tech employees, 3 of them are have more than 20 years industry experience and 20 of them have more than 10 years, which greatly reduces customers’ communication costs and project development and manufacturing cycles. With the concept of "pragmatism", we provide customers with one-stop high-quality solutions from raw materials to process engineering and manufacturing.