Metal Parts Fabrication is a strong metal part made of Stainless steel,Aluminum, high carbon steel or galvanized steel through sheet metal, stamping, die-casting, forging, casting, powder metallurgy and other metal processing. It is widely used in ipping, medical, mining, automobile and aircraft manufacturing industries.For example,One of our most qualified products is Precision Aluminum Alloy Die Casting Radiator.

Metal Parts Fabrication can flexibly meet the various shapes of customized metal products in various industries. At the same time, Metal Parts Fabrication also has the advantages of high durability, easy maintenance, low cost, and environmental protection. Like Metal Accessories Casting Parts are the best application in industries field.

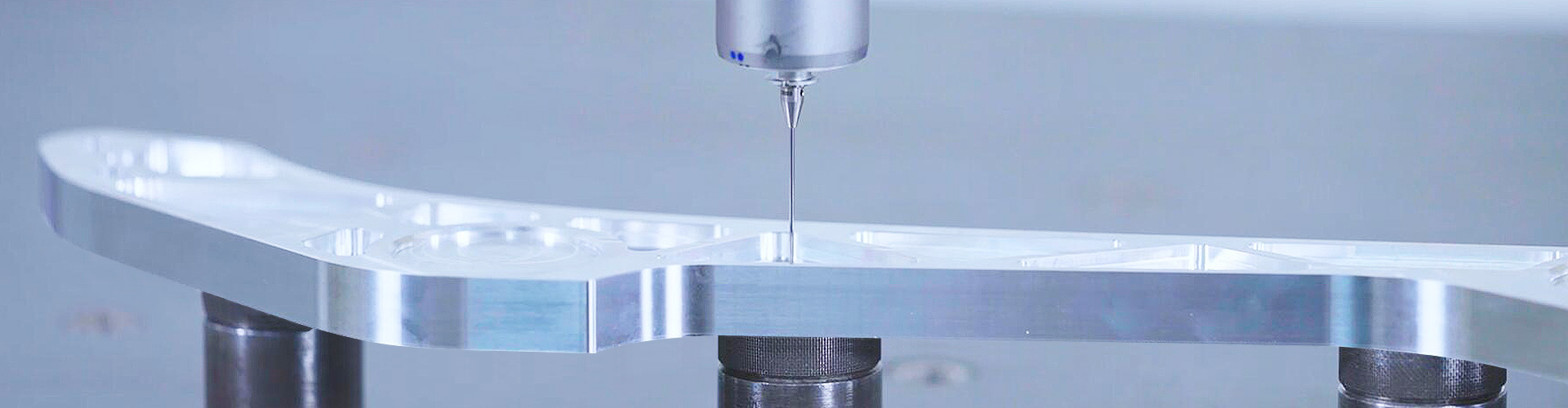

Automobile aluminum alloy forging parts With the development of the automobile industry, the number of global automobiles is increasing year by year, and various electric vehicles are also emerging. The resulting energy crisis, air pollution and climate warming are becoming more and more serious, and the governments of various countries have increasingly strict regulations on automobile emissions. Harsh. Whether it is for fuel vehicles or electric vehicles, automobile lightweight is an important means to effectively improve product competitiveness. One of the main ways is to replace traditional steel parts with lightweight metal parts, thereby reducing the emissions of fuel vehicles and improving the battery capacity of electric vehicles. battery life.

You can rest assured to buy Powder metallurgy stainless steel parts from our factory and we will offer you the best after-sale service and timely delivery. Stainless steel powder metallurgy, as the name implies, is stainless steel manufactured by powder metallurgy. Compared with stainless steel produced by traditional smelting processes, it has the advantages of close to net shape, high dimensional accuracy, high material utilization rate, and uniform structure.

You can rest assured to buy Automotive Custom Precision Forged Parts from our factory. Due to the high strength and good toughness of the parts manufactured by the forging process, they are suitable for mass production, so nearly 60% of the parts in the car are produced by forging. In recent years, with the rapid growth of automobile production, when various OEMs upgrade and integrate vehicle production capacity, the integration of parts and components is also being planned simultaneously.

You can rest assured to buy customized Zinc alloy die casting from us. Zinc alloy die-casting parts are zinc alloy materials that inject molten metal liquid into the cavity through pressure in the die-casting machine, and obtain the required parts after cooling, solidification, and cleaning.

You are welcomed to come to our factory to buy the latest selling, low price, and high-quality Powder metallurgy parts in brake booster vacuum pump. Vehicles equipped with gasoline engines, because the engine adopts ignition type, can generate high vacuum pressure in the intake manifold, which can provide sufficient vacuum source for the vacuum booster braking system. Most of the current vacuum pumps are connected to the intake manifold place. Gasoline direct injection engines designed to meet high emission environmental protection requirements cannot provide the same level of vacuum pressure at the intake manifold to meet the requirements of the vacuum brake booster system, so a vacuum pump needs to be installed.

As the professional manufacture, we would like to provide you Automotive precision forging parts. Due to the high strength and good toughness of the parts manufactured by the forging process, they are suitable for mass production, so nearly 60% of the parts in the car are produced by forging. More and more vehicle manufacturers are pursuing lightweight and fuel-saving rate, replacing cutting process with precision forging technology has become the main direction of new product development, all of which provide opportunities for the development of precision forging.