Buy High-performance wipers which is of high quality directly with low price. The wiper is a high-frequency component in the car, and it is constantly evolving. Sunbright has developed a high-performance wiper that combines washer fluid injection with built-in cleaning nozzles.

High-performance wipers

Buy High-performance wipers which is of high quality directly with low price. The wiper is a high-frequency component in the car, and it is constantly evolving. Sunbright has developed a high-performance wiper that combines washer fluid injection with built-in cleaning nozzles.

Product display

Product introduction

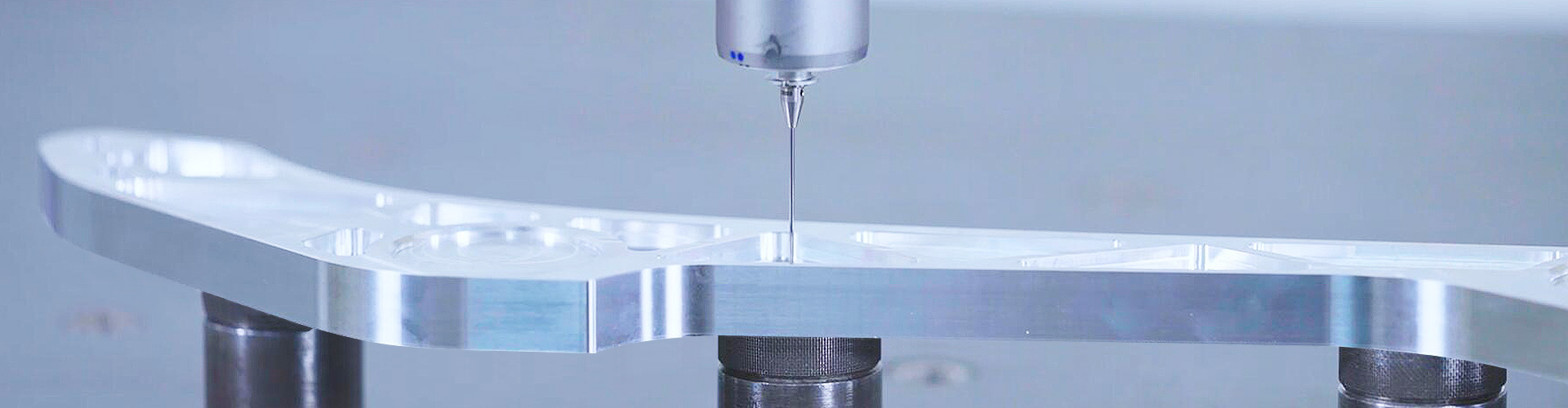

This wiper sets the spray source on the wiper arm, which brings the jet closer to the windshield, the wiper arm has 12 laser cut holes evenly distributed along the entire length, the hole diameter is much smaller than regular spray holes, so the fluid sprays The pressure is also higher and applied more evenly, resulting in a greater impact on dirty areas. Designers say that after many trials, setting the right number of injection holes, punching location and angle to ensure that the washer fluid is directed to its proper location, dirt and debris can be removed during the wiper's first motion stroke. was washed away. And with the old dual-nozzle system, the first stroke of the wiper felt less than satisfactory when cleaning the front glass with mud or bird droppings. For off-road vehicles and engineering vehicles that often take muddy roads, this is indeed a practical design. Of course, I hope it can be gradually extended to ordinary conventional vehicles to bring higher safety and comfort to vehicles!

Product tolerance:+/-0.005mm

FAQ

Who we are?

Shenzhen Sunbright Technology Co., Ltd. is a metal parts manufacturer integrating development, design, production and sales. The company has advanced mold manufacturing and casting die-casting, forging, stamping, extrusion, turning and milling composite CNC machining, etc. Product assembly manufacturing capabilities. Products are widely used in communications, instruments, medical equipment, high-speed rail, trains, automobiles, aviation, automation equipment and other industries. According to the needs of customers, we provide one-stop services such as production, processing, polishing, oil injection, corrosion, electroplating and assembly of molds and hardware metal parts.

What services can we provide?

We can provide CNC turning, milling, turning and milling composite services, our metal mold processing services include stamping, die casting, forging, casting, powder metallurgy, and we also provide injection molding services, etc. We can provide you with more than 50 kinds of metals and plastics Materials, our more than two dozen surface treatments including electroplating, anodizing, painting, etc., can tailor a part solution for you according to your needs.

How do we guarantee quality?

Sunbright has successively passed ISO9001 certification, passed AS9100 aerospace quality management system standard certification, NDT-MT passed NADCAP certification, introduced ERP system in 2018, and implemented lean production in 2020. The company has a professional management team, strong technical force, advanced Production equipment, high-precision monitoring and measuring equipment, and perfect management system provide customers with high-quality products and services.

What equipment do we have?

Sunbright has more than 1,000 sets of CNC machining, EDM, punch, die-casting machines, forging equipment, casting equipment, and injection molding equipment, which can manufacture high-precision parts for you.Our testing equipment includes German ZEISS CMM three-coordinate instrument, German SPECTRO MAXx06 Spectrometer direct reading spectrometer, American Micro-Vu CMM optical three-coordinate instrument; American AD-2045 wet horizontal magnetic detector, American projector, Japan Mitutoyo profilometer, American pneumatic measuring instrument, Italian SYSTEM AFFRI hardness tester, German GARDNER gloss meter, Japan Keyence optical caliper and other precision testing equipment.