We can manufacture all kinds of Five-axis linkage cnc precision machining parts, from auto parts, spare parts, facilities, mold parts, equipment parts, etc., from bicycle parts, wheelchair parts, machined parts, light heat link parts, mobile phone cases, etc., whatever you want to develop or build A prototype, you can send us your ideas or sketches, then our engineers discuss machining solutions with you for review.

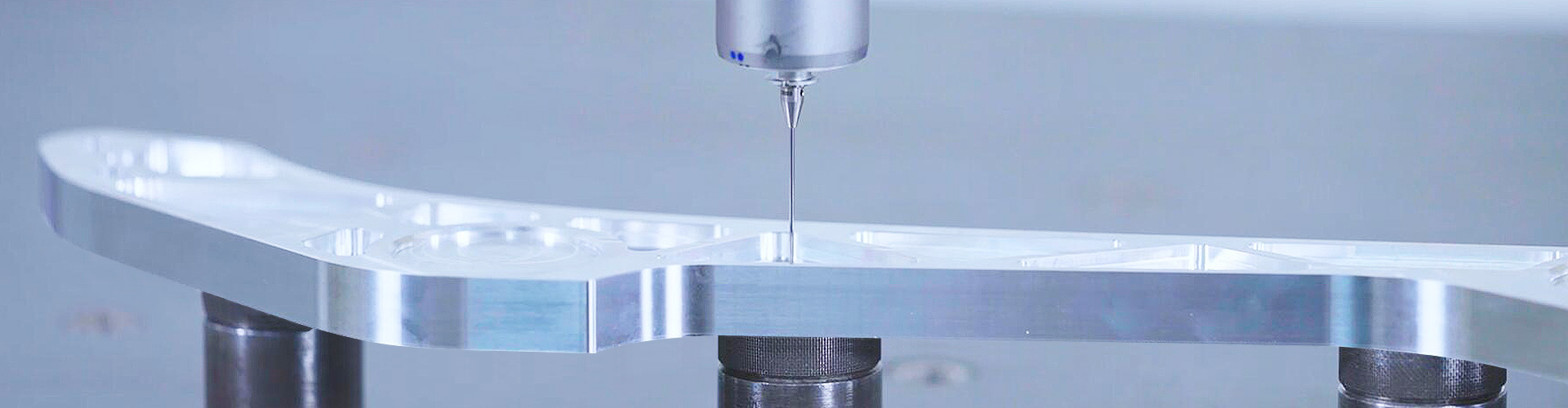

Five-axis CNC machining parts

As the professional manufacture, we would like to provide you Five-axis linkage cnc precision machining parts. And we will offer you the best after-sale service and timely delivery. We can manufacture all kinds of stainless steel parts, from auto parts, spare parts, facilities, mold parts, equipment parts, etc., from bicycle parts, wheelchair parts, machined parts, light heat link parts, mobile phone cases, etc., whatever you want to develop or build A prototype, you can send us your ideas or sketches, then our engineers discuss machining solutions with you for review.

Product display

Product introduction

A five-axis machining center can also be called a five-axis linkage machining center. There are five coordinate motion axes, which are two rotary motion coordinate axes and three linear motion coordinate axes. The five-axis machining center is more suitable for processing complex, multi-process, and high-precision parts. It requires a variety of ordinary machine tools, a variety of tools and fixtures, and has been clamped and processed many times. Five-axis machining centers have an important impact on core industries such as aerospace, military, scientific research, and medical machinery.

There are many benefits to machining parts with 5-axis CNC

1. Easy setup: 5-axis CNC machine, making it possible to easily machine complex shapes in one setup. It doesn't need to be set multiple times, which can lead to errors. A single setup helps reduce setup and manufacturing time and increase productivity. In addition to shortening lead times, this processing technique also helps to increase production and cash flow.

2. Faster cutting speeds: Since 5-axis CNC machining allows simultaneous movement along both X and Y axes, you can use shorter, stronger tools. Using shorter and stiffer cutting tools helps to cut faster with minimal or negligible vibration.

3. Improve precision: The workpiece does not move during 5-axis CNC machining, which can achieve higher part precision.

4. Superior finish: The shorter tooling used in the 5-axis CNC machining process helps to achieve a superior surface finish resulting in better part quality.

5. Ability to machine complex parts: With this machining technology, you can manufacture extremely complex machine parts in less time and at lower cost. This is a great benefit for applications or prototypes that are run on a small scale.

Product tolerance:+/-0.005mm

FAQ

Who we are?

Shenzhen Sunbright Technology Co., Ltd. is a metal parts manufacturer integrating development, design, production and sales. The company has advanced mold manufacturing and casting die-casting, forging, stamping, extrusion, turning and milling composite CNC machining, etc. Product assembly manufacturing capabilities. Products are widely used in communications, instruments, medical equipment, high-speed rail, trains, automobiles, aviation, automation equipment and other industries. According to the needs of customers, we provide one-stop services such as production, processing, polishing, oil injection, corrosion, electroplating and assembly of molds and hardware metal parts.

What services can we provide?

We can provide CNC turning, milling, turning and milling composite services, our metal mold processing services include stamping, die casting, forging, casting, powder metallurgy, and we also provide injection molding services, etc. We can provide you with more than 50 kinds of metals and plastics Materials, our more than two dozen surface treatments including electroplating, anodizing, painting, etc., can tailor a part solution for you according to your needs.

How do we guarantee quality?

Sunbright has successively passed ISO9001 certification, passed AS9100 aerospace quality management system standard certification, NDT-MT passed NADCAP certification, introduced ERP system in 2018, and implemented lean production in 2020. The company has a professional management team, strong technical force, advanced Production equipment, high-precision monitoring and measuring equipment, and perfect management system provide customers with high-quality products and services.

What equipment do we have?

Sunbright has more than 1,000 sets of CNC machining, EDM, punch, die-casting machines, forging equipment, casting equipment, and injection molding equipment, which can manufacture high-precision parts for you.Our testing equipment includes German ZEISS CMM three-coordinate instrument, German SPECTRO MAXx06 Spectrometer direct reading spectrometer, American Micro-Vu CMM optical three-coordinate instrument; American AD-2045 wet horizontal magnetic detector, American projector, Japan Mitutoyo profilometer, American pneumatic measuring instrument, Italian SYSTEM AFFRI hardness tester, German GARDNER gloss meter, Japan Keyence optical caliper and other precision testing equipment.