In order to improve the processing efficiency and precision of complex special-shaped products, technicians have been looking for effective and accurate processing methods. The emergence of turning and milling compound machining equipment provides an effective solution for improving the machining accuracy and efficiency of parts. Our custom turn-mill composite parts have stable machining quality and high machining accuracy, and are suitable for complex machining requirements.

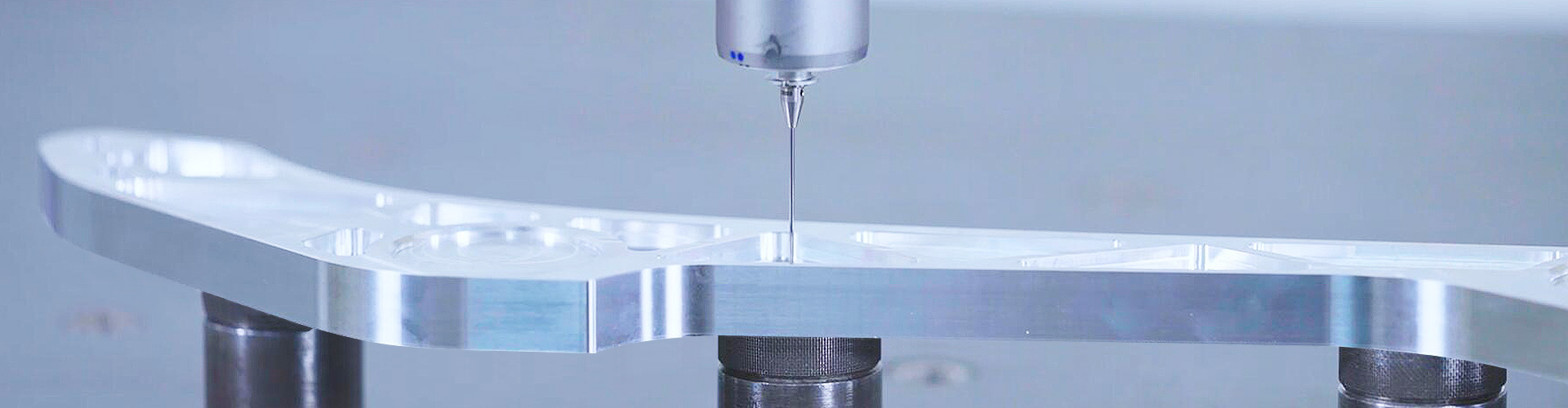

Custom turn-mill composite parts

In order to improve the processing efficiency and precision of complex special-shaped products, technicians have been looking for effective and accurate processing methods. The emergence of turning and milling compound machining equipment provides an effective solution for improving the machining accuracy and efficiency of parts. Our custom turn-mill composite parts have stable machining quality and high machining accuracy, and are suitable for complex machining requirements.

Product display

Product introduction

Compared with the parts processed by traditional CNC, the outstanding advantages of the custom turn-mill composite parts are mainly reflected in the following aspects:

(1) Shorten the product manufacturing process chain and improve production efficiency. Various special tools can be installed. The new tool arrangement reduces tool change times and increases machining efficiency. Turn-milling can complete all or most of the machining operations at one time, thereby greatly shortening the product manufacturing process chain. On the one hand, the auxiliary production time caused by the replacement of the fixture can be reduced, the manufacturing cycle and waiting time of the fixture can be reduced, and the production efficiency can be greatly improved.

(2) Reduce clamping time and improve machining accuracy. Reducing load time avoids the accumulation of errors caused by translation of positioning data. At the same time, most turn-milling composite processing equipment has online detection function, which can realize on-site detection and precise control of key data in the manufacturing process, thereby improving the processing accuracy of products. The design of the high-strength integral bed improves the gravity machining capability of difficult-to-cut materials. The machine is equipped with an automatic feeding device, which can realize continuous and continuous automatic feeding, and basically realize single-bed assembly line operation.

(3) Reduce floor space and production costs. The compact and beautiful appearance design improves space utilization, makes maintenance and repairs more convenient, and makes customers extremely satisfied. Although the price of single-cycle milling compound processing equipment is relatively high, due to the shortening of the manufacturing process chain and the reduction of equipment required for products, as well as the reduction in the number of fixed equipment, workshop area and equipment maintenance costs, it can effectively reduce the total investment in fixed assets, Production, operating and administrative costs.

Product tolerance:+/-0.005mm

FAQ

Who we are?

Shenzhen Sunbright Technology Co., Ltd. is a metal parts manufacturer integrating development, design, production and sales. The company has advanced mold manufacturing and casting die-casting, forging, stamping, extrusion, turning and milling composite CNC machining, etc. Product assembly manufacturing capabilities. Products are widely used in communications, instruments, medical equipment, high-speed rail, trains, automobiles, aviation, automation equipment and other industries. According to the needs of customers, we provide one-stop services such as production, processing, polishing, oil injection, corrosion, electroplating and assembly of molds and hardware metal parts.

What services can we provide?

We can provide CNC turning, milling, turning and milling composite services, our metal mold processing services include stamping, die casting, forging, casting, powder metallurgy, and we also provide injection molding services, etc. We can provide you with more than 50 kinds of metals and plastics Materials, our more than two dozen surface treatments including electroplating, anodizing, painting, etc., can tailor a part solution for you according to your needs.

How do we guarantee quality?

Sunbright has successively passed ISO9001 certification, passed AS9100 aerospace quality management system standard certification, NDT-MT passed NADCAP certification, introduced ERP system in 2018, and implemented lean production in 2020. The company has a professional management team, strong technical force, advanced Production equipment, high-precision monitoring and measuring equipment, and perfect management system provide customers with high-quality products and services.

What equipment do we have?

Sunbright has more than 1,000 sets of CNC machining, EDM, punch, die-casting machines, forging equipment, casting equipment, and injection molding equipment, which can manufacture high-precision parts for you.Our testing equipment includes German ZEISS CMM three-coordinate instrument, German SPECTRO MAXx06 Spectrometer direct reading spectrometer, American Micro-Vu CMM optical three-coordinate instrument; American AD-2045 wet horizontal magnetic detector, American projector, Japan Mitutoyo profilometer, American pneumatic measuring instrument, Italian SYSTEM AFFRI hardness tester, German GARDNER gloss meter, Japan Keyence optical caliper and other precision testing equipment.