Nowadays, almost every manufacturing industry uses computer numerical control or CNC machines. From the production of auto parts to the production of aviation and aerospace, CNC precision machining is ubiquitous. Highly recommend one of our superior projects is Complex Muli-axis Linka CNC Parts In Aero-engine.

Why choose CNC precision machining? CNC precision machining is an advanced automated machining technology with high precision and high efficiency. It greatly reduces the processing time and effectively solves the processing of complex and precise parts.

Sunbright is a leading China manufacturer of high-end CNC precision parts in the industry. Sunbright has 34 sets of CNC turning lathe, 150 sets of CNC milling machines with rotary index from USA, Japan, Taiwan and Korea,which can meet the processing of high-precision aircraft, electronic communications, medical equipment, and other parts. Hold ISO9001 and AS9100 certification.

The company is for over 20 years, NADCAP- NDT(magnetic particle inspection) certified in 2019, and also has implemented an ERP system since 2018 and lean manufacturing system since 2020.

Medical precision parts produced by sunbright include a variety of surgical instruments used in medical procedures, such as trocars (skin piercers), bone drills and saws. When cnc is used to machine medical precision parts, the part is usually milled using 3 to 5 axes or turned using a live tool CNC lathe. The most common types of machines used in the manufacturing of medical parts include CNC milling, lathing, drilling, and computerized milling.

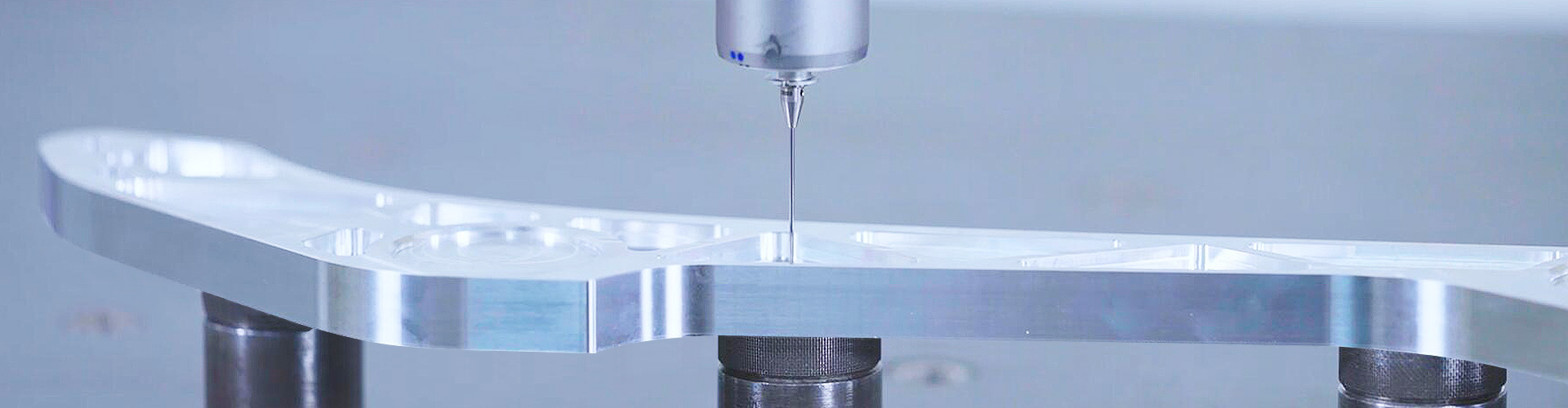

In order to improve the processing efficiency and precision of complex special-shaped products, technicians have been looking for effective and accurate processing methods. The emergence of turning and milling compound machining equipment provides an effective solution for improving the machining accuracy and efficiency of parts. Our custom turn-mill composite parts have stable machining quality and high machining accuracy, and are suitable for complex machining requirements.

Sunbright specializes in cnc processing, aluminum parts processing, CNC lathe processing, machining, precision parts processing, turning parts, turning parts processing, stainless steel parts processing, aluminum alloy processing, processing materials including but not limited to various types of stainless steel, aluminum alloy, yellow Copper, etc. The tolerance of CNC machinery precision shaft accessories we process can reach 0.005mm, and we can undertake customized processing of various types of precision shaft accessories according to user needs.

Our Custom cnc milling machined parts can produce custom prototypes and end-use production parts within 1 day. We use 3-axis milling ~ 5-axis indexing milling process to manufacture parts from more than 30 engineering grade magnesium alloy materials and aluminum alloys, stainless steel. We support turnkey completion to meet the visual and functional requirements of any design.

You can rest assured to buy customized Aluminum turning parts from us. Sunbright is an enterprise engaged in CNC machining of aluminum alloy parts, focusing on CNC machining and customization of aluminum alloy, stainless steel, copper, titanium alloy, ceramics and other materials, metal casings, and precision parts. Our aluminium turning parts offer many advantages when it comes to machining. For example, the processing quality is stable, the processing accuracy is high, and the repeatability is good; the production efficiency is improved in the case of multi-variety and small batch production. Reduce the time for production preparation, adjustment and process inspection; it can process complex profiles and some unobservable processing parts that are difficult to process by conventional methods.

Precision Machined Extruding Radiator Fin heats the aluminum ingot to a certain temperature according to the requirements of the drawing and the corresponding mold to change its physical form. And then comes out of the mold to get the various heat sinks we want .That is what we call Extruded heat sink, which is made by cutting, CNC machining and surface treatment. It is an excellent heat dissipation material widely used in modern heat dissipation. Most of the industry uses aluminum 6063-T5 high-quality aluminum. Because its purity can reach More than 98%, its thermal conductivity is strong, the density is low and the price is low. So it has been favored by major manufacturers.