Nowadays, almost every manufacturing industry uses computer numerical control or CNC machines. From the production of auto parts to the production of aviation and aerospace, CNC precision machining is ubiquitous. Highly recommend one of our superior projects is Complex Muli-axis Linka CNC Parts In Aero-engine.

Why choose CNC precision machining? CNC precision machining is an advanced automated machining technology with high precision and high efficiency. It greatly reduces the processing time and effectively solves the processing of complex and precise parts.

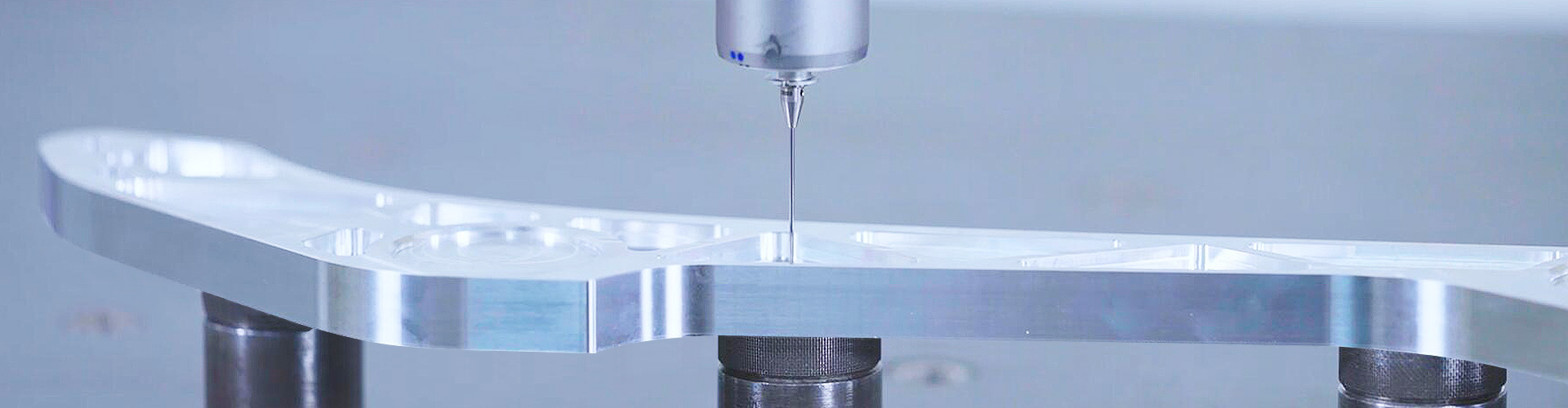

Sunbright is a leading China manufacturer of high-end CNC precision parts in the industry. Sunbright has 34 sets of CNC turning lathe, 150 sets of CNC milling machines with rotary index from USA, Japan, Taiwan and Korea,which can meet the processing of high-precision aircraft, electronic communications, medical equipment, and other parts. Hold ISO9001 and AS9100 certification.

The company is for over 20 years, NADCAP- NDT(magnetic particle inspection) certified in 2019, and also has implemented an ERP system since 2018 and lean manufacturing system since 2020.

We supply High Precision Medical Components Cnc Metal Parts with the process of CNC machining and deburring. High-precision tolerance is controlled within 0.01mm.The company have been passed ISO9001& AS 9100D certified for over 20 years. The factory area is approximately 50,000 square meters with more than 1,000 sets of various advanced production machines and 20 sets of high-precision inspection equipment.

In the field of UAV CNC machining precision parts, various intelligent products emerge in endlessly. Now the most popular intelligent CNC precision parts processing is UAV. The full name of UAV is "UAV", which involves propulsion technologies such as sensors, communications, information processing, and intelligent control technology. It is an unmanned aircraft operated by radio remote control equipment and self-contained program control. The value of UAVs lies in the formation of an aerial platform, combined with other components to expand applications, and replace humans to complete operations in the air

We can manufacture all kinds of Five-axis linkage cnc precision machining parts, from auto parts, spare parts, facilities, mold parts, equipment parts, etc., from bicycle parts, wheelchair parts, machined parts, light heat link parts, mobile phone cases, etc., whatever you want to develop or build A prototype, you can send us your ideas or sketches, then our engineers discuss machining solutions with you for review.

We can manufacture all kinds of cnc machining stainless steel parts, from auto parts, spare parts, facilities, mold parts, equipment parts, etc., from bicycle parts, wheelchair parts, machined parts, light heat link parts, mobile phone cases, etc., whatever you want to develop or build A prototype, you can send us your ideas or sketches, then our engineers discuss machining solutions with you for review.

Magnesium alloy CNC medical parts have light specific gravity, high specific strength, good electromagnetic shielding performance, good shock resistance, easy processing, recyclability and good biocompatibility and degradability. They are used in 3C products, automobiles, aerospace and biological It has broad application prospects in the medical field. Population aging has become an increasingly serious social problem in our country, which has brought a huge demand for biomedical materials such as bone implant materials. As a new type of biodegradable biomedical materials, medical magnesium alloys, such as cardiovascular stents and bone implant materials (bone nails, bone plates, etc.), have become the hotspots of current frontier research.

You can rest assured to buy CNC processing plastic prototype from our factory. CNC plastic processing is the main method of prototype production, mainly to process plastic materials such as ABS, PC, PA, PMMA, POM into the physical samples we need. CNC-processed samples have the advantages of large size, high strength, good toughness, and low cost, and have become the mainstream of prototype production.