The machinability of aluminum alloy turning parts is a general term for aluminum-based alloys. By adding alloying elements such as Cu, Si, Mg, Zn, Mn, etc., while maintaining the advantages of pure aluminum and light weight, its alloy is greatly improved. "Strength", some types can approach or exceed high-quality steel, and become an ideal structural material, which is widely used in machinery manufacturing, transportation machinery, power machinery and aviation industry.

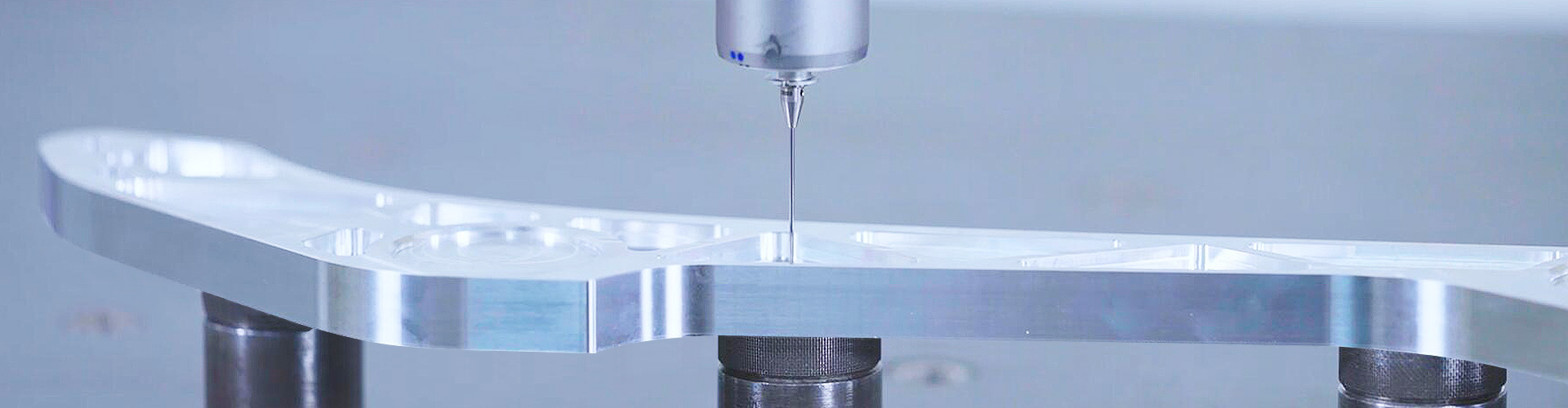

Aluminum alloy turning parts

The machinability of aluminum alloy turning parts is a general term for aluminum-based alloys. By adding alloying elements such as Cu, Si, Mg, Zn, Mn, etc., while maintaining the advantages of pure aluminum and light weight, its alloy is greatly improved. "Strength", some types can approach or exceed high-quality steel, and become an ideal structural material, which is widely used in machinery manufacturing, transportation machinery, power machinery and aviation industry.

Product display

Product introduction

From the machinability of aluminum alloy turning parts, it can be seen that no matter which cutting type is used in turning (boring), milling, and drilling, the tool is required to be wear-resistant, the cutting edge is sharp, and the rake angle is large. The design features are large, the main declination angle is large, the auxiliary declination angle is small, the blade inclination angle is a positive angle, and the blade surface is smooth and clean.

1.Front corner

Under the condition of maintaining the strength of the blade, choosing a large rake angle can grind a sharp edge on the one hand, and on the other hand, it can reduce the cutting deformation, make the chip removal smooth, and then reduce the cutting force and cutting temperature. Never use negative rake angle knives

2.Back corner

The size of the relief angle has a direct impact on the wear of the flank and the quality of the machined surface. The cutting thickness is an important condition for selecting the clearance angle. During rough milling, due to the large feed rate, heavy cutting load and large heat generation, the tool requires good heat dissipation conditions, and the clearance angle should be selected to be smaller. When fine milling, the cutting edge is required to be sharp, the friction between the flank face and the machined surface is reduced, and the elastic deformation is reduced, and the clearance angle should be larger.

3.Main declination

Appropriately reducing the main declination angle can improve the heat dissipation conditions and reduce the average temperature of the processing area.

Product tolerance:+/-0.005mm

FAQ

Who we are?

Shenzhen Sunbright Technology Co., Ltd. is a metal parts manufacturer integrating development, design, production and sales. The company has advanced mold manufacturing and casting die-casting, forging, stamping, extrusion, turning and milling composite CNC machining, etc. Product assembly manufacturing capabilities. Products are widely used in communications, instruments, medical equipment, high-speed rail, trains, automobiles, aviation, automation equipment and other industries. According to the needs of customers, we provide one-stop services such as production, processing, polishing, oil injection, corrosion, electroplating and assembly of molds and hardware metal parts.

What services can we provide?

We can provide CNC turning, milling, turning and milling composite services, our metal mold processing services include stamping, die casting, forging, casting, powder metallurgy, and we also provide injection molding services, etc. We can provide you with more than 50 kinds of metals and plastics Materials, our more than two dozen surface treatments including electroplating, anodizing, painting, etc., can tailor a part solution for you according to your needs.

How do we guarantee quality?

Sunbright has successively passed ISO9001 certification, passed AS9100 aerospace quality management system standard certification, NDT-MT passed NADCAP certification, introduced ERP system in 2018, and implemented lean production in 2020. The company has a professional management team, strong technical force, advanced Production equipment, high-precision monitoring and measuring equipment, and perfect management system provide customers with high-quality products and services.

What equipment do we have?

Sunbright has more than 1,000 sets of CNC machining, EDM, punch, die-casting machines, forging equipment, casting equipment, and injection molding equipment, which can manufacture high-precision parts for you.Our testing equipment includes German ZEISS CMM three-coordinate instrument, German SPECTRO MAXx06 Spectrometer direct reading spectrometer, American Micro-Vu CMM optical three-coordinate instrument; American AD-2045 wet horizontal magnetic detector, American projector, Japan Mitutoyo profilometer, American pneumatic measuring instrument, Italian SYSTEM AFFRI hardness tester, German GARDNER gloss meter, Japan Keyence optical caliper and other precision testing equipment.