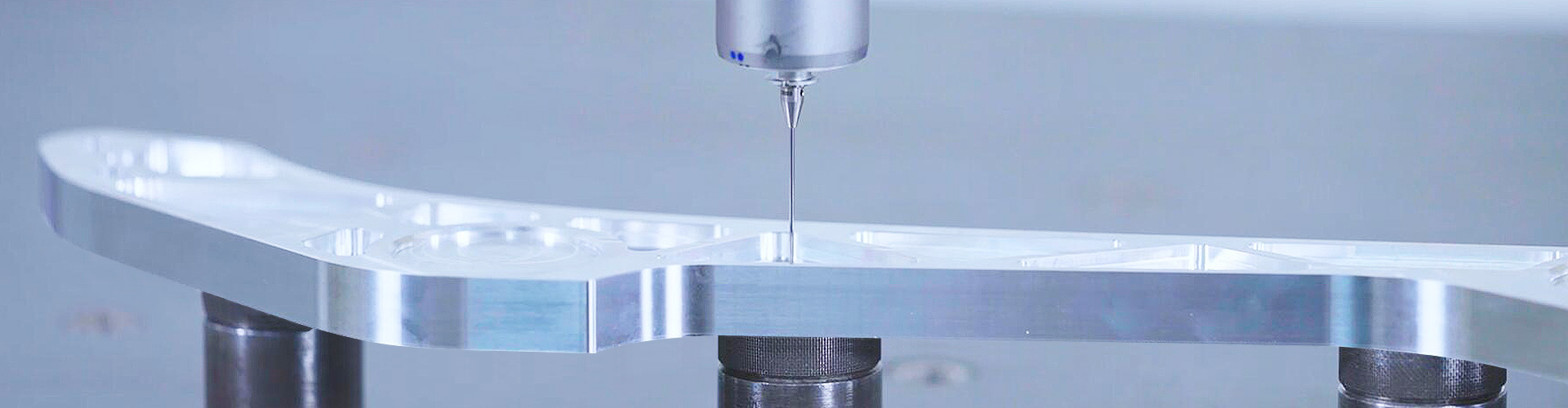

You can rest assured to buy Semiconductor Precision Parts from our factory. Semiconductor equipment has a complex structure consisting of thousands of components. The performance, quality and precision of components determine the reliability and stability of the equipment. The semiconductor industry follows the industrial law of "one generation of technology, one generation of technology, and one generation of equipment", and the upgrade and iteration of semiconductor equipment largely depends on the technological breakthrough of precision components. Various semiconductor components cooperate with each other to support the operation of semiconductor equipment. Compared with the basic components of equipment in other industries, the cutting-edge technical characteristics are more obvious, such as high precision, small batch, variety, special size, complex process, and strength. , strain, corrosion resistance, electronic characteristics, electromagnetic characteristics, material purity and other composite functional requirements.